Products

Cooling Towers.

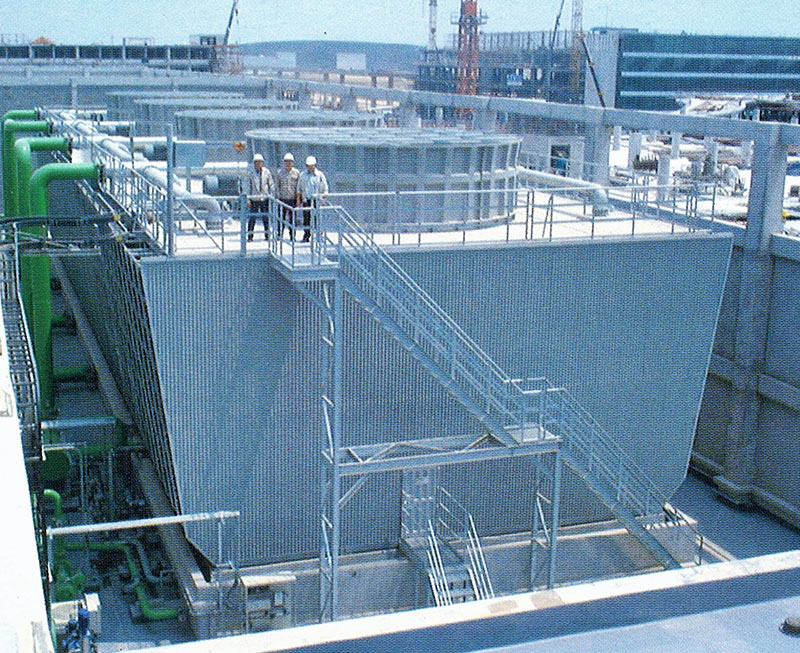

'MAPLETREE BUSINESS CITY'

SHINWA, a brand name under parent company Ebara Corporation, is synonymous with quality & reliable performance in cooling towers. Since its first production in 1955, it is now one of the leading brands and amajor player in the global market.

With EBARA’s corporate policy of “conserving water, air and the environment”, SHINWA’s cooling tower design has always been guided by energy and space savings, with minimal maintenance. It offers a lineup of models with excellent functions and a wide range of capacities that provide a stable supply of cooling water to various types of water-cooled air conditioning systems and industrial cooling applications.

Shinwa's ongoing commitment to research and development includes a very substantial facility for the complete performance capacity test ing of all its towers, which includes the ability to maintain controlled humidity and temperature.

Asiatic’s exclusive partnership with SHINWA commenced in 1992. Since then, Asiatic has supplied and installed in many iconic and important projects in Singapore and Vietnam, which includes about 80% of the Singapore Mass Rapid Transits (SMRT) train stations, Singapore Changi Airport Terminals, National Art Gallery, Mapletree Business City, Singapore Management University (SMU), HarbourFront ,Novartis Pharmaceuticals, numerous data centres, Saigon Centre, VIETCOM Bank, to name a few.

'MRT STATION . DOWNTOWN LINE'

COOLING TOWERS

Cross-Flow . ‘Square’ Type . SDC-U Model

SHINWA’s SDC-U Series, is a range of ‘induced-draft crossflow’ modular type cooling towers, with high efficiency heat exchange in-fills designed with drift eliminators incorporated as standard.

Each module of SDC-U, fitted with a super low noise type AVS fan, has a built-in piping arrangement for hot water return, with valve at each of the hot water basin to regulate the water flow to optimize heat rejection.

The SDC-U is designed to allow delivery in complete assembled form; or as semi-assembled form, i.e. with cooling tower body and fan section delivered separately. This off-site pre-assembly feature greatly reduce tower erection cost & time and facilitate installation where space is a constraint.

The structures of the cooling towers are hot-dipped galvanised steel, with stainless steel material as option. Stainless steel bolts & nuts are supplied as standard.

For ease of maintenance and servicing, the internal of the SDC-U is designed for easy access; and with FRP lower water basin sloped for easy cleaning. A new speed reducer SRS with wedge belt is compact and increase the ease for maintenance.

'HARBOUR FRONT'

COOLING TOWERS

Cross-flow . ‘Square’ Type .

SNC-U Model

Energy-saving. Space-saving. Light weight…These are features of SHINWA’s SNC-U Series. It is a range of induced-draft crossflow cooling towers, designed with smaller foot-print for installation site where space is a constraint.

SNC-U model has newly developed high-efficiency heat exchange in-fills, designed with drift eliminators incorporated as standard. And combined with the super low noise type AVS fan and reduction in installation space, as well as light dry & operating weight, the SNC-U series can be up to 20% more compact compared with SHINWA’s predecessor models.

To reduce tower assembly cost & time, and where work site is a constraint for assembly work; the SDC-U range is designed to allow delivery to site in complete assembled or as semi-assembled form (i.e. with cooling tower body and fan section delivered separately). The towers are usually assembled off-site before delivery and hoisted to position on site.

The structures of the cooling towers are hot-dipped galvanised steel, with stainless steel material as option. Stainless steel bolts & nuts are supplied as standard.

For ease of maintenance and servicing, the internal of the SDC-U is designed for easy access; and with FRP lower water basin sloped for easy cleaning. A new speed reducer SRS with wedge belt is compact and increase the ease for maintenance.

'NOVARTIS SINGAPORE'

COOLING TOWERS

Closed-circuit . Cross-flow Type . MXC-UW Model

The MXC series is a ‘closed-circuit’ cooling tower which is designed for processes where the cooling water must be isolated from the airstream to prevent fouling. The MXC is configured as cross-flow for lowest energy consumption when compared against a counter-flow closed circuit tower. A very unique feature of this series is its cooling coils made of copper, for reliable and very long service life.

COOLING TOWERS

Industrial Cross-flow Type .

SLC Model . SCC Model

For large capacity industrial or district cooling applications, SHINWA offers the SLC & SCC Series. The SLC and SCC is a range of induced-draft crossflow and counterflow type cooling towers, respectively.

The fans are made of light weight FRP of high efficiency design and is driven by a low noise gear drive system.

COOLING TOWERS

Cooling Tower Performance Assessment . Maintenance & Services

To ensure that our cooling towers in existing installations continue to operate to specifications, Asiatic provides to our clients services to perform ‘health checks’ on our towers.

Our qualified team of technicians can provide assessment of the physical conditions of the cooling towers, as well as its performance. A report would generally be submitted upon assessment, outlining the performance status of the towers as well as to recommend work to be done; and if required, parts to be replaced so as to bring the equipment to performing to their optimum again.

.jpg)

.png)

.jpeg)

.jpg)

.jpg)

.jpg)

.jpg)